in the Middle East

in the Middle East

PEX “ Industrial Co., Ltd”

Pioneers in manufacturing heavy duty pipes and accessories in the Arab world and the Middle East

About Us

We are a large economic industrial entity bearing the name “PEX Industrial Company Ltd.”, established in 1986 with the purpose of manufacturing heavy duty pipe tubes and accessories for the growing market in the Arab region and the Middle East.

Over the course of nearly three and a half decades, we have succeeded in occupying the forefront Pex system, the leading interlocking polyethylene pipe in the manufacture of plastic pipes for hot and cold water pipes, which provides unparalleled advantages in this field.

Vision

We aspire to be the first of the leading companies in the industrial sector locally, regionally and internationally, and we strive to achieve the best level of customer satisfaction by providing high-quality products at competitive prices.

Mission

At Pex, we are committed to providing high-quality industrial products that meet customer requirements, satisfy their tastes, and achieve their goals

Values

Stems from the main rules of success, which are excellence and accuracy, taking care of the customer and the worker, accountability and transparency, and the most important of which are cooperation and consolidating the spirit of one team and teamwork in a way that constitutes a strong work environment capable of creating effective and successful plans.

What is PEX

What is PEX ??

Diversity of use

Easy of transportation and storage

Thermal memory

Immediate repair

50 Years Except Misuse

البكس نوع من الصناعات البتروكيميائية المشتقة من البترول وبالتحديد من مادة الايثيلين وهي غاز أو سائل أو حبيبات يرمز لها علميًا بالحرف “Pex” وعند تسخين هذه المادة ووضعها تحت ضغط معين يتغير تركيبها من ايثيلين إلى عديد الايثيلين المعروف بالبولي إيثيلين وينتمي عديد الإيثيلين والمواد البلاستيكية الأخرى كالبولسترين إلى مجموعة تسمى ثيرموبلاستيك، أوالبلاستيك الحراري هذه المواد تلين في درجات حرارة معينة وإذا تكررت عملية التعيين بالحرارة فإن هذه المواد تفقد خواصها الميكانيكية مما يفقدها صلاحية الاستخدام

وقد طور العالم الكيميائي الألماني توماس أنجل منذ عدة عقود عديد الإيثيلين ذا الكثافة العالية الى عديد الايثيلين المدعم المترابط شبكياً ، ومادة البكس تنتمي الى مجموعة البوليستر غير المشبع والأيوكسي ومواد أخرى حيث تدعي هذه بالثرموست ومن المعروف أن العناصرالمكونة لعديد الإيثيلين (البولي ايثيلين) هي الكربون والهيدروجين وهما متصلتان بعضهما ببعض بشكل منظم عن بعدين وبعد إخضاعها لعملية العالم توماس أنجل اصبحت متشابكة ومتصلة مع بعضها بعضأ في ثلاثة أبعاد، حيث إن السلاسل الجزيئية ليست متصلة ومتجاورة فقط بل وبدون نظام معين بحيث لا يمكن أن تتحرك هذه الجزيئيات عند ارتفاع درجة الحرارة وهذا على خلاف عديد الإيثيلين الذي يلين بتكرار عملية التليين بالحرارة

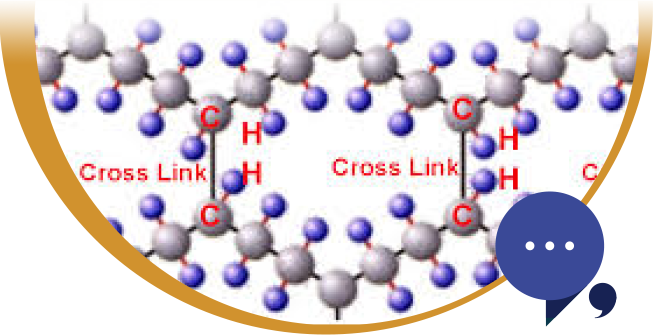

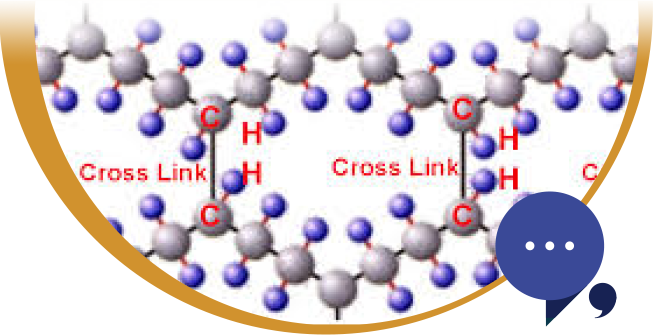

Technical history for PEX system

PEX is a type of petrochemical industries derived from petroleum, specifically from Ethylene, which is a gas, means or granules, which are symbolized by a scientific letter (PEX), and when this material is heated and placed under a certain pressure, its composition changes from ethylene to polyethylene. The polyethylene and other plastics such as polystyrene belong to a group called thermoplastic, these materials soften at certain temperatures, and if the process of determination of heat is repeated, these materials lose their mechanical properties, which makes them lose their validity for use.

The German chemist Thomas Engel developed a high-density polyethylene Decades ago into a reinforced polyethylene bonded mesh, and the PEX material belongs to the group of unsaturated polyester, oxy and other materials, where these are called thermostats. Carbon and hydrogen, which are connected to each other in an orderly way from two dimensions, and after subjecting them to the process of the scientist Thomas Angel, they became intertwined and connected to each other in three dimensions, as the molecular chains are not only connected and contiguous, but without a specific system so that these particles cannot move at high temperature and this Unlike polyethylene, which softens by repeating the thermoplastic process

Cables Insulated with Cross-LAD X LINK Polyethylene ``LAD X LIN``

LAD X LINK are plastics made from crosslinkable polyethylene that are chemically manufactured by treating polyethylene using a compound “Siloxane”. It is one of the best materials for producing structures for low pressure (LV) cables.

GRAFTING and crosslinking activation are done in one step in the production line. The rate of hydrotherapy can be controlled by varying the local humidity. The crosslinking process can be completed within 3 to 7 days by storing the product outdoors, exposing it to sunlight and moisture. In arid regions, it is necessary to wet the produced cables from 3 to 7 days before exposure to sunlight.

Since all the additional materials are in LAD X LINK plastics, therefore, there is no need to pre-mix any other ingredients (except for coloring materials when needed). Lad X link plastics can be supplied upon request with special colored materials and with anti-sun fasteners to insulate suspended cables.